Products

The W-SCOPE Group is engaged in the manufacture and sale of membrane films, such as separators for lithium-ion secondary batteries and ion exchange membranes, utilizing its unique polymer film technology.

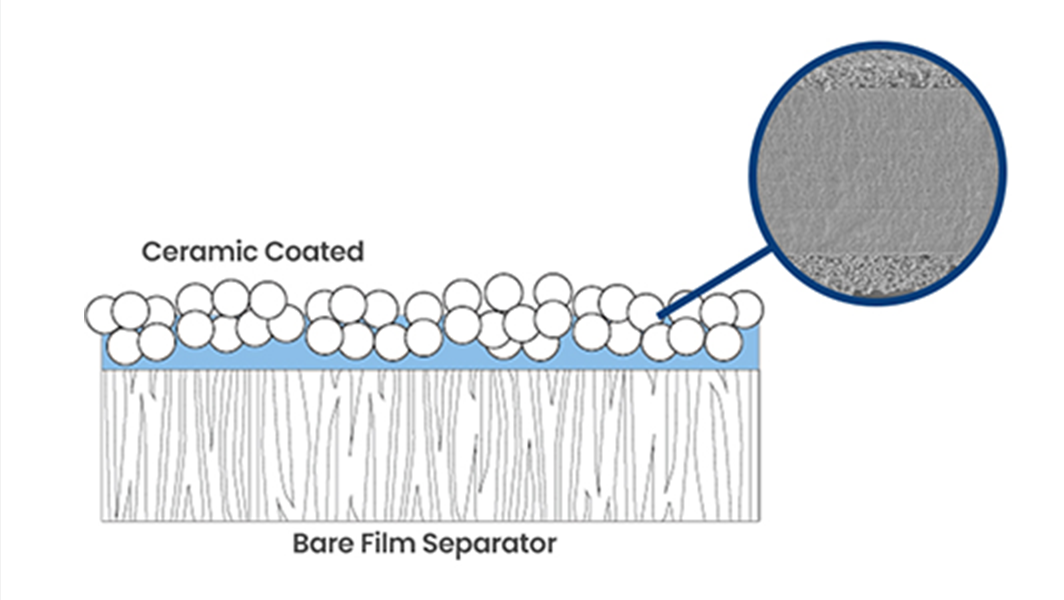

Bare/CSS

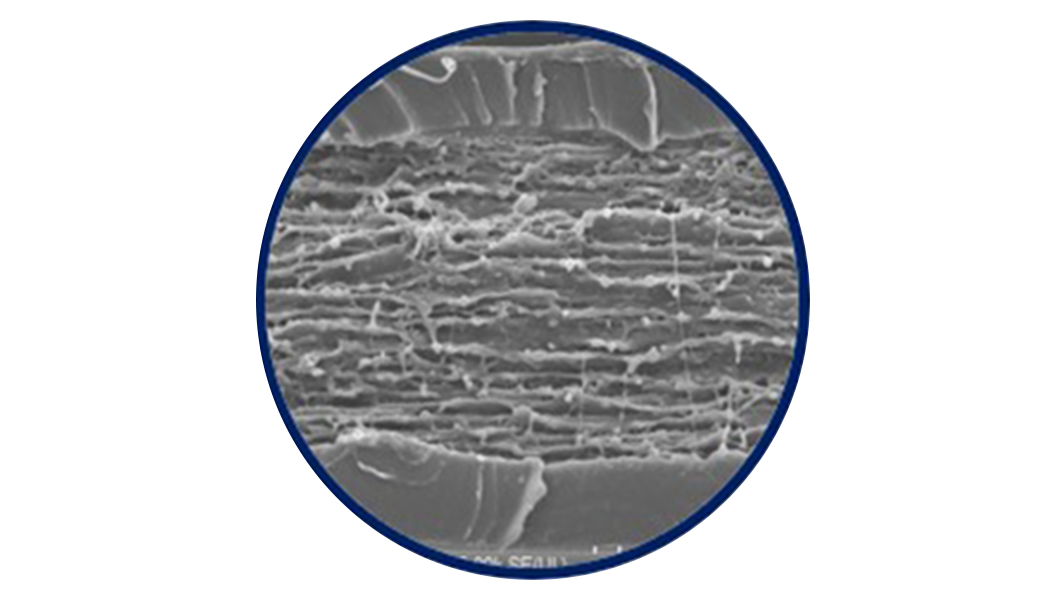

Bare Film Separator

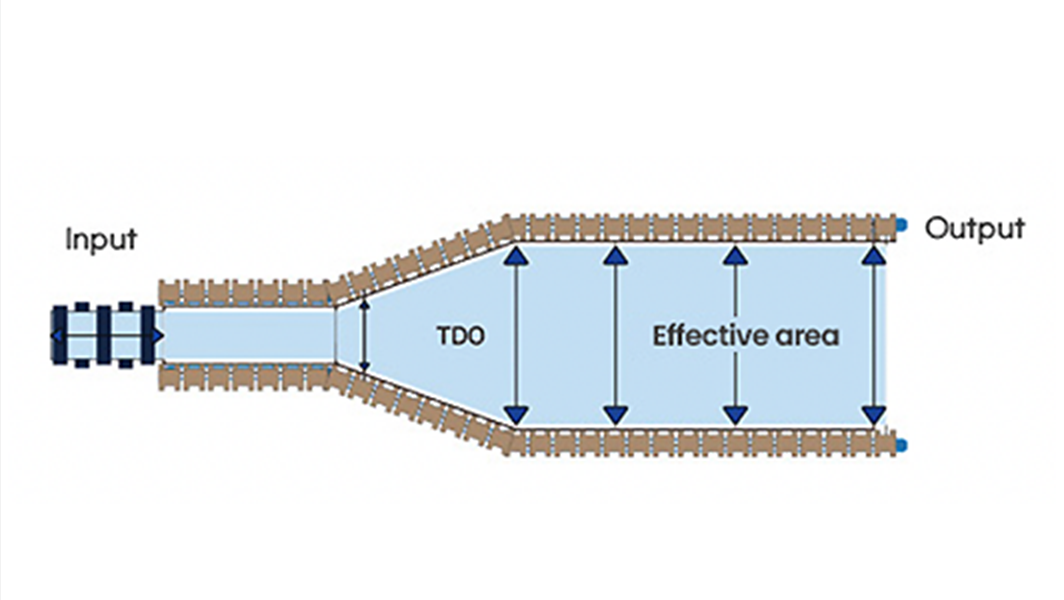

WCP – Sequential

Stretching Process

- Faster production speed

- Require advanced technology

- High uniformity

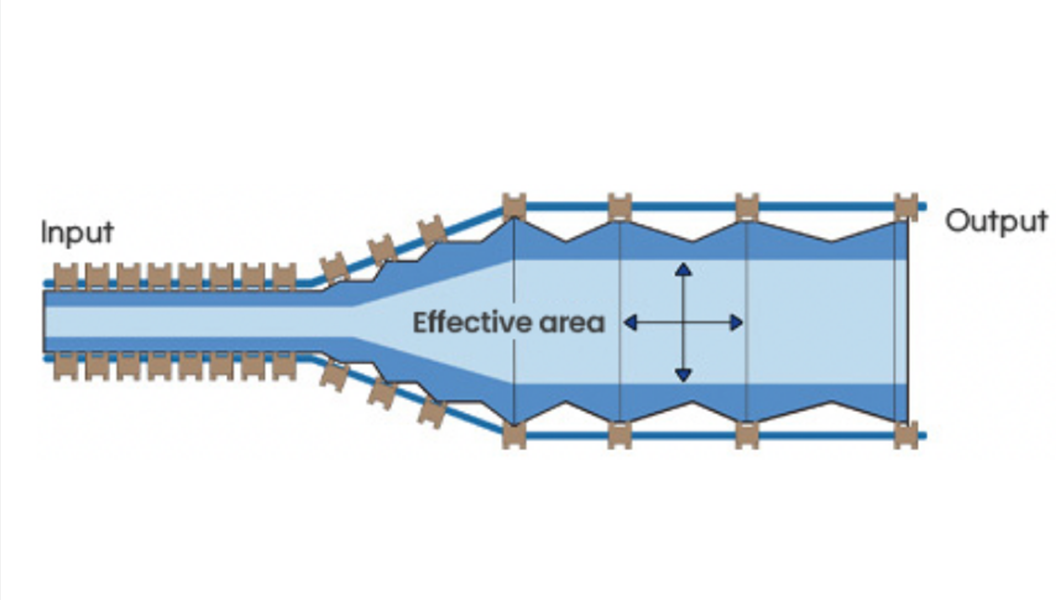

Other Manufacturers - Simultaneous Stretching Process

- Lower ratio of effective area

- Stretching rate fixed at up to 6 times

- Difficult to implement strength in certain level

Ceramic Coated Separator

- Use environmentally friendly water-based slurry which requires high technology

- Secure the health of the workers

- Cost reduction by securing yield through stable production

- 2.2x increased productivity through proprietary coating technology

- Proprietary binder synthesis technology

| Classification | Past | Present | Future |

|---|---|---|---|

Bare Flim |

12 ~ 25 ㎛ | 9 ~ 12 ㎛ | Customized R&D (Improvement in strength and thinning) |

コーティング |

20 ~ 24 ㎛ | 13 ~ 16 ㎛ |

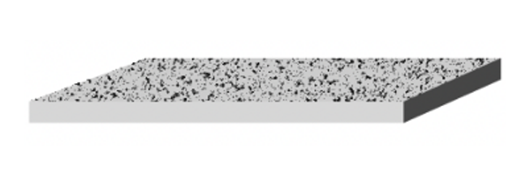

Ion-Exchange Membrane

W-SCOPE's Ion Exchange Membrane

- Secure competitiveness through the application of pore control technology.

- Produce products selectable with a thickness range of 10um ~ 200umby independent porous support

- Production of eco-friendly hydrocarbon-based support

- A superior gap in productivity through the possession of unique technology

- Possession of ionomer technology and impregnation technology

Ion exchange membrane manufacturing process

-

Raw material selection

Ionomer and catalyst dispersion technology -

Ionomer Development

Ionomer synthesis technology -

Porous Support Development

Pore control technology of porous support -

Optimization of Film Forming Technology

Large area film forming technology -

Secure Mass Productivity

Properties of our ion exchange membrane

| Classification | Homogeneous Membrane  |

W-SCOPE's Complex Electrolyte Membrane |

Heterogeneous Membrane  |

|---|---|---|---|

| Thickness of membrane | 50~100μm | 10~100μm | 300~500μm |

| Technology Level | Low | High | Low |

| Application | Narrow | Wide | Narrow |

| Production speed | Low | High | Low |

| Price | High | Affordable | High |